Perhaps you have never heard of Industrie De Nora, yet this Made in Italy company has a profound impact on our daily lives. It is, in fact, a global benchmark in the electrochemical industry and a leading manufacturer of electrodes for major industrial electrochemical processes. In addition to developing innovative and sustainable technologies, the company produces water purification systems used worldwide.

Over a century of creativity and pioneering spirit

De Nora has maintained a perfect blend of technology, creativity and a pioneering spirit for more than a century. It was founded in 1923 by engineer Oronzio De Nora, born in 1899, originally from Altamura, who had moved to Milan to study electrochemistry at the Politecnico. The proceeds he received from developing a plant to produce sodium hypochlorite more efficiently enabled him to found the company.

Sodium hypochlorite, used in the textile industry as a bleaching agent and in photographic printing processes as a fixative, is produced via an electrolytic cell. By 1922, Oronzio had obtained his first patent, an electrolytic cell that made the hypochlorite production process more efficient. And it was thanks to this first invention that Oronzio made another: Amuchina, a powerful disinfectant destined to spread rapidly throughout the world. In the 1930s, however, he sold the patent to focus on developing industrial cells for chlor-alkali plants.

The DSA® anode revolution

By the early 1930s, De Nora had already achieved great success in producing sodium hypochlorite plants. However, new technologies were emerging, including the chlor-alkali production process, which was initially carried out with mercury cathode cells. This is where De Nora focused his research, intending to perfect this type of cell. By using new materials and other innovations, he optimised the system, resulting in significant energy savings. In addition, the systems were more reliable and effective, so much so that from the early 1950s until the mid-1970s, 40 per cent of the world’s chlorine production was made with De Nora technologies.

Mercury cathode cells use graphite anodes, which are brittle and prone to wear. That’s how Oronzio came up with the idea of making anodes from a metal not subject to deterioration. After years of research, titanium metal anodes were developed and equipped with a special coating perfected by De Nora. Patented under the DSA® trademark, they represent a revolution in chlor-alkali production, allowing the company to make a huge leap in quality.

An (almost) revolutionary idea: the Ferrari for everyone

De Nora’s story is not only about chemistry and innovation but also about bold dreams. In the 1960s, Niccolò De Nora, the founder’s son and a lover of sports cars, decided to help Enzo Ferrari produce the “Ferrarina,” a small Ferrari accessible to a broader public. Thus, ASA (Autocostruzioni Società per Azioni) was born, a fascinating gamble that did not lead to the hoped-for success. After this interlude in the car world, the company returned to focus on what it did best: innovating in electrochemistry.

A journey through innovation

Innovation is thus in De Nora’s DNA. The company has filed more than 3,500 patents, marking milestones in electrochemistry and environmental purification.

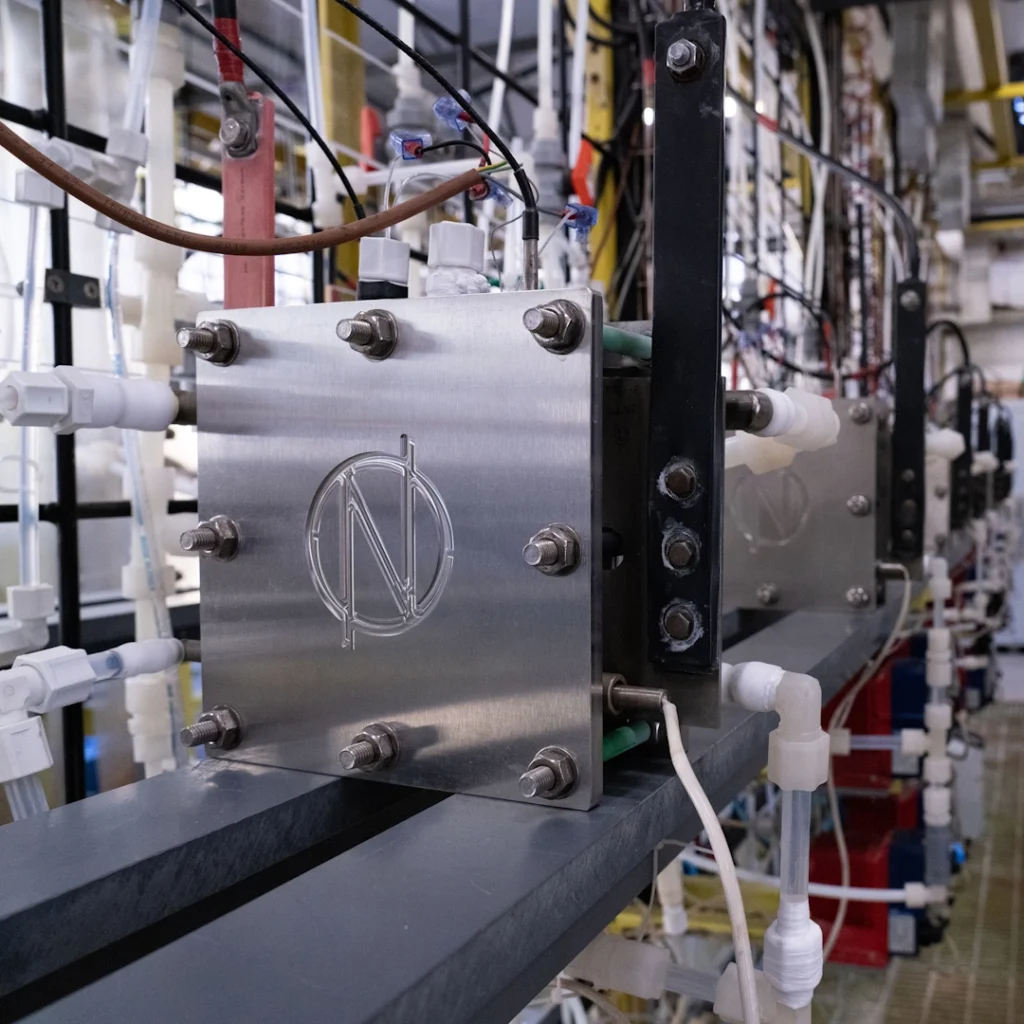

De Nora has always invested in the search for solutions to improve everyone’s lives, from sanitisation to clean energy, and today, it is a leading player in the energy transition with cutting-edge projects such as the Italian Gigafactory, dedicated to the production of electrolysers to generate green hydrogen, which is essential for a zero-emissions future. With an area of 25,000 square meters and a full production capacity of 2 GW, it will be the largest gigafactory in Italy and the most advanced ever built by De Nora.

A company that speaks the language of the future

From Milan to Singapore, from Tokyo to São Paulo, De Nora is present in 10 countries with 24 companies. This global expansion has enabled the company to stay one step ahead, developing cutting-edge environmental and industrial sustainability solutions. All without losing its family spirit and taste for research, just as it did in the early days.

In 2022, De Nora took the big step of listing on the stock exchange, with an initial capitalisation of 2.7 billion euros. But success is not just in the numbers: it is in the ability to constantly innovate, finding solutions for the future of energy, water, and industry. It is a mix of vision, expertise and a great desire to improve the world, one patent at a time.

Congratulations to those who bring Italian chemistry and technology to the world by innovating.

Learn about other outstanding Made in Italy companies in the world of chemistry.